News

-

hibot Corporation Secures Investment from Terna Forward(the Terna Group company dedicated to Corporate Venture Capital) to Accelerate Robotic Solutions for Live Power Line Maintenance and Critical Infrastructure

-

hibot to Showcase Advanced Robotics Solutions at iREX 2025 in Tokyo

-

Exhibition of Expliner-T at the Italy Pavilion, Osaka-Kansai EXPO2025

Changing the Way We Inspect and Maintain Infrastructure—Today

Towards a Safer and Sustainable World with Robotics

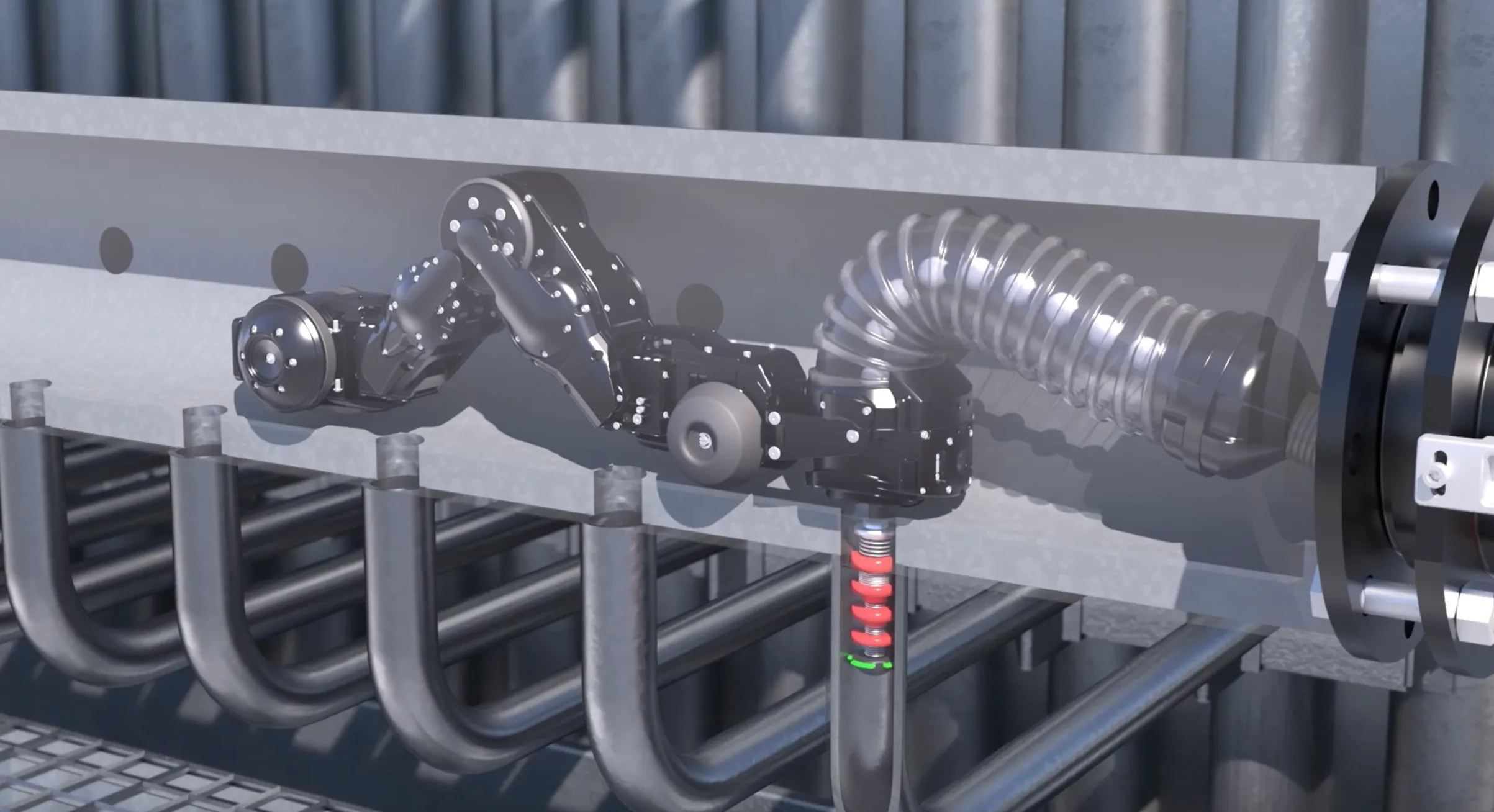

Hibot, a venture from the Tokyo Institute of Technology,

has as its mission to create a safer and sustainable world with robotics. Hibot’s Float Arm, the long-reach arm robot system, derived from the work in the decommissioning of the Fukushima n.1 Nuclear Power Plant, is now deployed globally for infrastructure inspection and maintenance.

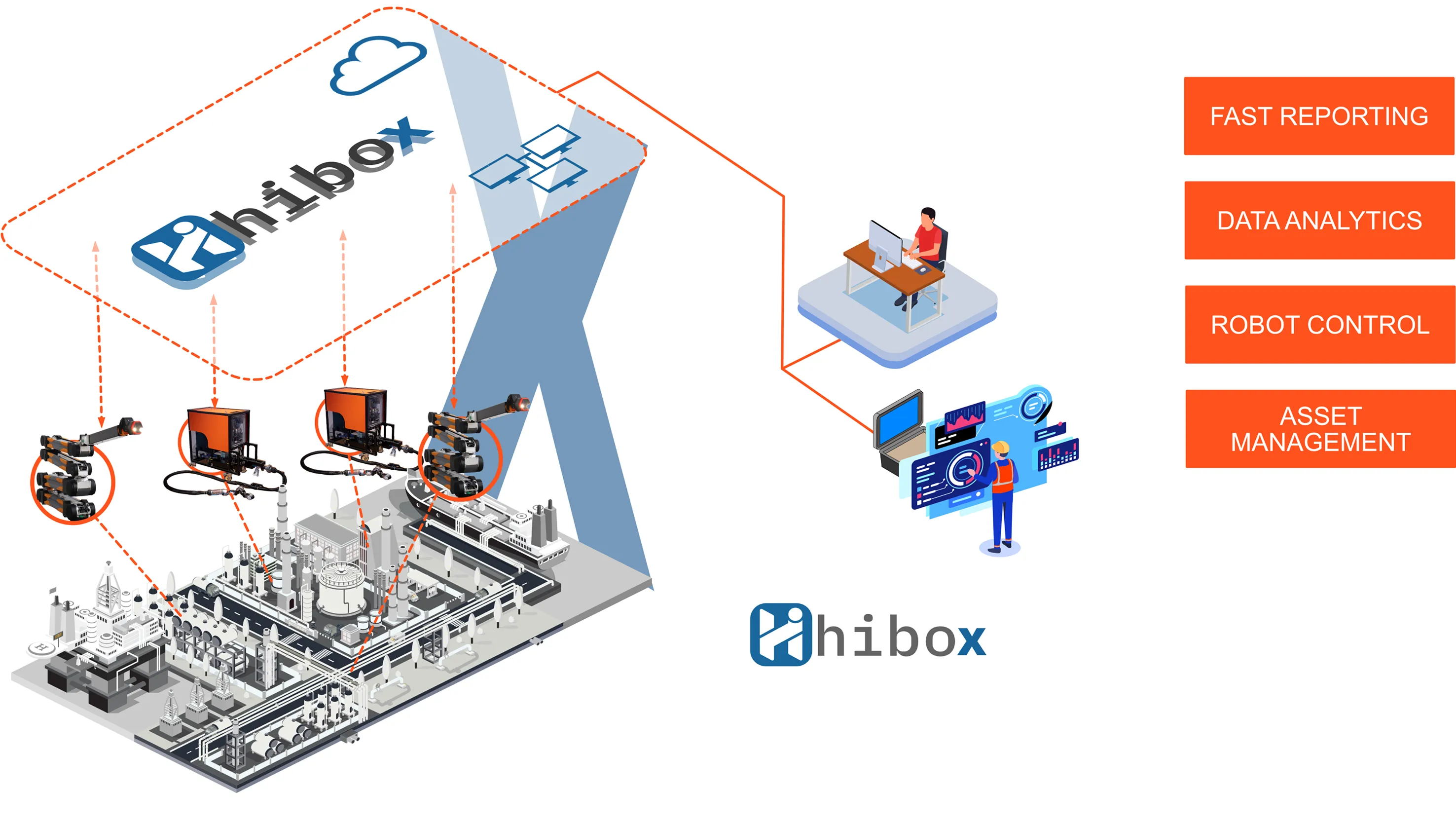

Our robotic solutions, combined with Hibox and its AI-powered predictive maintenance, transform power, oil, gas and chemical industries, leading the digital transformation as the next-generation game-changer.

Efficiency Improved

by Over 5 Times

Day

Efficiency Improved

by Over 5 Times

“Inspection tasks, that normally took 5 to 6 days, are now possible in

just one day” [customer feedback].

The decrease of even one day of downtime results in substantial cost advantages for our customers.

Day

Overall Cost

Reduction

%

Overall Cost

Reduction

Cost can be reduced by as much as 30% with the use of

hibot’s robotic solutions.

The use of Float arm makes operations safer and cheaper. The use of scaffoldings, lean operations and internal approval processes are drastically reduced, if not removed.

%

Service

We introduce robotic tools designed for precise and advanced inspection and maintenance